Mon - Fri 8:00am - 6:00pm

Give us a call:

Engine Walnut Blasting: Unveiling the Secret to Restoring BMW Performance with Carbon Cleaning

C Deselle • December 20, 2024

When it comes to maintaining the optimal performance of your BMW, regular maintenance is key. While routine services like oil changes and filter replacements are well-known, there's another crucial procedure that often goes unnoticed: engine walnut blasting. In this blog post, we'll delve into the benefits of walnut blasting your engine, its significance for your vehicles, and how it can breathe new life into your car's performance.

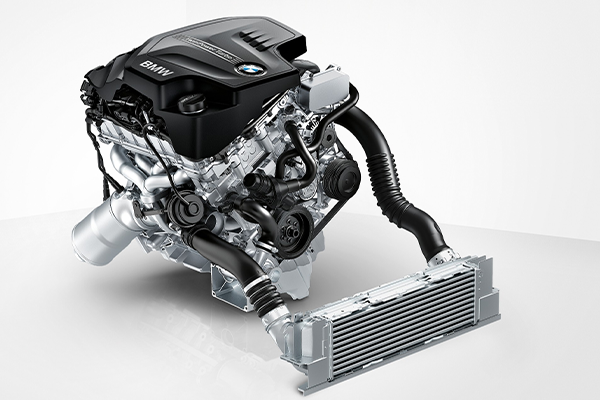

Engine walnut blasting, also know as Carbon Cleaning, is a process that entails cleaning the intake manifold and valves of a car's engine with a high pressure air blast of finely crushed walnut shells (a biodegradable abrasive). This specialized procedure is meant to help clear out carbon buildup from the intake valves and ports of direct injection engines. Over time, these carbon deposits can build up, obstructing airflow, and compromising engine performance.

BMW vehicles, particularly those equipped with direct injection engines, are prone to carbon buildup. This accumulation can result in a host of issues, including reduced fuel efficiency, loss of power, rough idling, and increased emissions. Engine walnut blasting is specifically recommended for BMWs to effectively combat these problems and restore the vehicle's performance and efficiency.

In direct injection engines, fuel is injected directly into the combustion chamber, skipping the intake valves that would traditionally be cleaned by the fuel's detergent properties. As a result, carbon deposits can form on the intake valves and ports, hindering the proper flow of air and fuel mixture.

Yes, real walnut shells are used in the process of engine walnut blasting. Engine walnut blasting involves using finely crushed walnut shells as an abrasive media to clean carbon deposits from the intake valves and ports of a direct injection engine. The crushed walnut shells are propelled by compressed air and directed into the intake manifold, where they make contact with the carbon deposits. As the walnut shells come into contact with the deposits, they act as a gentle abrasive, effectively dislodging and removing the carbon buildup from the surfaces. This process helps restore proper airflow and improve engine performance. It's important to note that the walnut shells used in engine walnut blasting are specifically processed and formulated for this purpose and are not the same as whole walnuts found in grocery stores.

Engine walnut blasting involves using finely crushed walnut shells as a blasting medium. The walnut shells are directed into the intake manifold, where they are propelled by compressed air. As they make contact with the carbon deposits, the walnut shells act as a gentle abrasive, dislodging and removing the buildup from the intake valves and ports.

Here's how the process works:

Preparation: The first step is to prepare the vehicle for walnut blasting. This typically involves disconnecting the necessary components to gain access to the intake manifold and removing the necessary parts to create a clear pathway for the walnut blasting equipment.

Walnut Blasting Equipment: Specialized walnut blasting equipment is used for this procedure. The equipment consists of a blasting gun or wand that delivers the crushed walnut shells and a source of compressed air to propel the media.

Media Introduction: The crushed walnut shells, which act as an abrasive media, are loaded into the blasting equipment. The walnut shells are finely crushed to ensure they are effective in removing carbon deposits but gentle enough not to cause damage to the engine components.

Blasting Process: With the engine running at a specified RPM, the technician inserts the blasting wand into the intake manifold. The compressed air propels the walnut shell media into the intake manifold, where it makes contact with the carbon deposits on the intake valves and ports.

Carbon Deposit Removal: As the walnut shell media comes into contact with the carbon deposits, it acts as a gentle abrasive. The media effectively dislodges and removes the carbon buildup from the surfaces of the intake valves and ports. The process continues until the technician ensures that the deposits have been thoroughly removed.

Cleaning and Inspection: After the walnut blasting is complete, the intake manifold and related components are cleaned to remove any remaining walnut shell media and carbon residue. The technician carefully inspects the cleaned surfaces to ensure that all the carbon deposits have been successfully removed.

Reassembly: Once the cleaning and inspection are complete, any disconnected components are reinstalled, and the intake system is reassembled.

Final Checks: The engine is started and tested to verify that it is running smoothly and that the carbon deposit removal has improved performance and restored optimal airflow.

Engine walnut blasting is a specialized procedure that should be performed by experienced technicians who are familiar with the process and have the necessary equipment. It is an effective method to remove carbon deposits and restore engine performance in direct injection engines.

Benefits of Engine Walnut Blasting for BMWs:

Improved Performance: Carbon deposits on the intake valves restrict the smooth flow of air, resulting in reduced engine power and responsiveness. Engine walnut blasting effectively removes these deposits, allowing for improved airflow, better combustion, and ultimately, enhanced engine performance.

Increased Fuel Efficiency: With clean intake valves, the fuel and air mixture can be optimally regulated, leading to improved fuel efficiency. Engine walnut blasting can help restore lost mileage and save you money at the pump.

Restoration of Engine Smoothness: Carbon deposits can cause rough idling and uneven engine operation. By eliminating these deposits, engine walnut blasting helps restore engine smoothness, resulting in a more enjoyable driving experience.

Reduction in Emissions: Carbon buildup can contribute to increased emissions, negatively impacting the environment. Engine walnut blasting helps reduce emissions by restoring the engine's efficiency and ensuring proper fuel combustion.

Prolonged Engine Life: Carbon deposits can lead to inefficient combustion and increased wear on engine components. By eliminating these deposits, engine walnut blasting can help extend the lifespan of your engine, reducing the risk of costly repairs in the future.

Why Trust a Professional BMW Repair Shop for Engine Walnut Blasting?

Engine walnut blasting requires specialized tools, equipment, and expertise to ensure a thorough and effective cleaning process. Entrusting this procedure to a professional BMW repair shop ensures that trained technicians with in-depth knowledge of BMW engines handle the job with precision and care. They have the experience to properly diagnose carbon buildup, perform the walnut blasting procedure, and conduct any necessary follow-up inspections or adjustments.

Engine walnut blasting is a powerful maintenance procedure that should not be overlooked when it comes to preserving the performance, efficiency, and longevity of your BMW. By removing carbon deposits from the intake valves and ports, this procedure unleashes the true potential of your engine, providing a smoother ride, improved fuel economy, reduced emissions, and increased engine lifespan.

If you own a BMW and notice signs of reduced performance or rough idling, consider engine walnut blasting as a solution. Call TMJ Bimmers today and let our skilled technicians revitalize your car's performance through this essential procedure. Experience the difference firsthand and enjoy the thrill of driving your BMW as it was meant to be.

By C Deselle

•

March 28, 2025

As a proud Porsche owner, you know your car is more than just a mode of transportation—it’s a masterpiece of engineering, performance, and luxury. However, like any high-performance vehicle, your Porsche is equipped with a variety of warning lights on the dashboard designed to keep you informed about its health. Understanding these lights is crucial for maintaining your Porsche in peak condition. This guide will walk you through the most common Porsche warning lights, explain what they mean, and provide guidance on the necessary actions to take when they appear. Why Warning Lights Matter Warning lights serve as your Porsche’s way of communicating potential issues, ranging from minor concerns to critical problems requiring immediate attention. These alerts can range from simple reminders, such as a low fuel warning, to serious issues like engine or braking system malfunctions. Ignoring these warnings can lead to costly repairs or even hazardous situations on the road. By understanding these indicators, you can take the appropriate actions to ensure your Porsche continues to run smoothly and efficiently. 1. Check Engine Light (CEL) What It Looks Like: A yellow or amber outline of an engine, sometimes with the word "CHECK." What It Means: This light indicates that the vehicle’s onboard diagnostics system has detected an issue. The cause could range from something minor, like a loose gas cap, to more serious problems, such as engine misfires, faulty oxygen sensors, or catalytic converter issues. What to Do: If the light is steady, schedule a diagnostic check as soon as possible. If it's flashing, it indicates a severe issue that requires immediate attention—pull over and have your Porsche towed to a repair shop to prevent engine damage. 2. Battery Warning Light What It Looks Like: A red battery icon. What It Means: This indicates that your Porsche’s battery is not charging properly, which could be due to a failing alternator, a weak battery, or corroded connections. What to Do: Reduce electrical usage and drive to a service center immediately. If the battery is completely discharged, your Porsche may not restart. 3. Brake Warning Light What It Looks Like: A red circle with an exclamation point inside or the word "BRAKE." What It Means: This could indicate low brake fluid levels, worn brake pads, or an issue with the braking system. What to Do: Check if your parking brake is engaged. If the light remains on, have your brakes inspected immediately at TMJ Bimmers to ensure safety. 4. Oil Pressure Warning Light What It Looks Like: A red oil can symbol with a drip. What It Means: Low oil pressure, which may result from low oil levels, a failing oil pump, or an oil leak. What to Do: Pull over immediately and check the oil level. If adding oil doesn’t resolve the issue, have your Porsche towed to a service center to prevent engine damage. 5. ABS (Anti-lock Braking System) Warning Light What It Looks Like: A yellow or amber circle with the letters "ABS." What It Means: There is an issue with your Porsche’s anti-lock braking system, which helps maintain control during hard braking. What to Do: While regular brakes may still function, have the ABS system inspected as soon as possible to avoid compromised braking performance. 6. Tire Pressure Monitoring System (TPMS) Light What It Looks Like: An exclamation point inside a horseshoe shape. What It Means: One or more tires are underinflated, which can impact handling and fuel efficiency. What to Do: Check tire pressure and inflate to the recommended levels. If the light persists, have the TPMS system checked. 7. Coolant Temperature Warning Light What It Looks Like: A red thermometer symbol. What It Means: Your Porsche's engine is overheating, possibly due to low coolant levels or radiator issues. What to Do: Pull over immediately, turn off the engine, and allow it to cool. Check coolant levels and top off if needed, but seek professional service if the problem persists. 8. Airbag Warning Light What It Looks Like: A person with an airbag in front. What It Means: There is a malfunction in the airbag system, which may prevent airbags from deploying properly in an accident. What to Do: Have the system inspected immediately to ensure safety. 9. Engine Temperature Warning Light What It Looks Like: A red thermometer submerged in liquid. What It Means: The engine is running hotter than normal, often due to low coolant, a failing water pump, or a faulty thermostat. What to Do: Pull over, allow the engine to cool, and check coolant levels. If the light stays on, have the vehicle towed to TMJ Bimmers to avoid potentially catastrophic engine damage. 10. Steering Wheel Warning Light What It Looks Like: A yellow or red steering wheel icon. What It Means: A problem with the power steering system, making steering more difficult. What to Do: Drive cautiously and schedule a service appointment. 11. Transmission Warning Light What It Looks Like: A gear with an exclamation point or the word "TRANS." What It Means: There is a problem with the transmission system, such as low fluid levels or mechanical failure. What to Do: Avoid hard accelerations and schedule a transmission inspection immediately. 12. Fuel Indicator Light What It Looks Like: A yellow gas pump icon. What It Means: Your fuel level is low, usually at 10-15% capacity. What to Do: Refuel as soon as possible to prevent running out and avoid damage to the fuel pump. Why Choose TMJ Porsche Specialists for Diagnostic Testing? While some warning lights may have simple solutions, others require expert diagnosis and repair. Porsches are complex, high-performance vehicles that demand specialized care. At TMJ Bimmers, we have the expertise and advanced equipment to accurately diagnose and repair any Porsche issues. Our team understands Porsche-specific systems, ensuring your vehicle receives the best possible care. Conclusion Understanding your Porsche’s warning lights is essential for keeping your vehicle in peak condition. By addressing these alerts promptly, you can prevent minor issues from escalating into costly repairs. If you’re unsure about a warning light or need expert advice, contact TMJ Bimmers Euro Car Care at 713.384.2273. We’re here to ensure your Porsche remains a top-performing machine on the road.

By C Deselle

•

March 14, 2025

BMW is a brand synonymous with performance, luxury, and driving pleasure. But for those who crave an extra level of speed, precision, and adrenaline, BMW’s M-Series—often called “M Cars”—stands at the pinnacle of automotive excellence. If you’ve ever wondered what makes an M Car different from a standard BMW, this article will dive into its history, origins, various models, and what sets these high-performance machines apart. The Origin of BMW M Cars BMW M, short for BMW Motorsport GmbH, was established in 1972 as the performance division of BMW. Originally, the M division was created to support BMW’s racing efforts, developing high-performance engines, chassis, and aerodynamics to compete in various motorsport events. The first major success of BMW M was in racing, particularly with the legendary BMW 3.0 CSL, a car that dominated the European Touring Car Championship in the 1970s. The success of BMW’s racing program led to the idea of bringing motorsport technology to road cars, and thus, the M Series was born. The First M Car: The BMW M1 (1978) The first-ever BMW M car was the BMW M1 , introduced in 1978. Designed as a mid-engine supercar, the M1 was built for homologation purposes—meaning BMW had to produce road-legal versions of the car to compete in motorsport events. It featured a 3.5L inline-six engine producing 273 horsepower, an impressive figure for its time. However, due to production difficulties, only 453 M1s were ever made, making it one of the rarest and most collectible BMWs today. Evolution of the M Series: A Look at the Key Models After the M1, BMW shifted its focus to high-performance versions of its standard production models. Let’s take a look at some of the most iconic M cars throughout history. BMW M3 (E30, 1986-Present) The BMW M3 is arguably the most famous M car. It debuted in 1986 with the E30 generation as a homologation special for DTM (Deutsche Tourenwagen Masters) racing. The E30 M3 featured a high-revving 2.3L four-cylinder engine and a lightweight chassis, making it one of the best-handling sports sedans of its time. Since then, the M3 has evolved through multiple generations, with each one bringing more power and advanced technology. Modern M3s feature turbocharged inline-six engines and optional all-wheel drive, but they retain the spirit of precision and performance that made the original legendary. BMW M5 (E28, 1984-Present) The M5 is the high-performance version of the BMW 5 Series and is known as one of the fastest sedans in the world. The first M5 (E28) arrived in 1984 with a 3.5L inline-six engine producing 282 horsepower, making it the fastest production sedan of its time. Over the years, the M5 has continued to push the limits of performance sedans. The E60 M5 (2005-2010) is particularly notable for its 5.0L V10 engine, which revved up to 8,250 RPM and produced an exhilarating exhaust note. Today’s M5 models use twin-turbocharged V8 engines, offering immense power while still providing everyday luxury and comfort. BMW M4 (F82, 2014-Present) Introduced in 2014, the M4 replaced the M3 Coupe as the high-performance two-door variant. It featured a 3.0L twin-turbocharged inline-six engine, producing over 400 horsepower. The latest G82 M4 offers even more power, aggressive styling, and an available all-wheel-drive system for enhanced traction and performance. Other Notable M Cars BMW M2 – A compact, high-performance coupe that delivers the raw driving pleasure of early M3 models. BMW M8 – A luxury grand tourer with supercar levels of power and performance. BMW X5M/X6M – High-performance SUVs that blend speed with practicality. What Makes an M Car Special? While a standard BMW is already a great driver’s car, M Cars take it to another level. Here’s what makes them superior: 1. More Powerful Engines M Cars receive specially tuned engines that deliver significantly more power and performance. These engines often feature lightweight components, advanced cooling systems, and higher redlines compared to their standard BMW counterparts. 2. Enhanced Suspension & Handling BMW M models come with sportier suspensions, upgraded brakes, and precise steering. Many models also offer adaptive dampers, allowing drivers to adjust ride stiffness for daily comfort or track-ready performance. 3. Aerodynamic & Lightweight Construction M Cars often feature aggressive bodywork, including larger air intakes, rear spoilers, and carbon fiber components to improve aerodynamics and reduce weight. 4. Unique M Features & Design From M-specific steering wheels and sport seats to customizable drive modes and exclusive badges, BMW M models are designed to offer a more engaging and immersive driving experience. 5. Track-Ready Performance Whether it’s on the highway or the race track, M Cars are built to handle extreme driving conditions. Many models include features like launch control, drift modes, and high-performance tires. Why Choose an M Car Over a Regular BMW? For some drivers, a regular BMW is enough—but for those who want more excitement, an M Car is the ultimate choice. M Cars are built with enthusiasts in mind, offering sharper handling, better acceleration, and an overall more engaging driving experience. However, owning an M Car also comes with additional considerations. These high-performance vehicles require more specialized maintenance, premium fuel, and sometimes higher insurance costs. But for those who love driving, the added costs are well worth it. Final Thoughts BMW’s M-Series cars represent the pinnacle of the brand’s engineering and motorsport heritage. Whether it’s the legendary M3, the high-speed M5, or the track-focused M4, each M Car offers an unparalleled blend of performance, luxury, and driving excitement. If you’re considering stepping into the world of M Cars, be prepared for a thrilling ride! At TMJ Bimmers, we specialize in servicing and maintaining BMW M models, ensuring that your high-performance machine runs at its peak. Whether you need routine maintenance, performance upgrades, or repairs, our expert technicians are here to help. Call us at 713.384.2273 or book your service now https://sgenie.io/lreaa to keep your M Car in top shape!

By C Deselle

•

February 12, 2025

Oil leaks are one of the most common issues BMW owners encounter. While these leaks might seem like minor inconveniences, ignoring them can lead to costly repairs and potentially serious damage to your engine. At TMJ Bimmers, we’ve seen and repaired countless BMW oil leaks, and three culprits consistently top the list: valve cover leaks, oil filter housing gasket leaks, and oil pan gasket leaks. Let’s break down these issues, their causes, and how they can be resolved. 1. Valve Cover Gasket Leak What It Is: The valve cover sits on top of your BMW’s engine and seals the valve train. Over time, the gasket that seals the valve cover becomes brittle and starts to leak. This is particularly common in models like the BMW 3 Series, 5 Series, and X Series vehicles, especially those with higher mileage. Signs of a Problem: A burning oil smell due to oil dripping onto the exhaust manifold. Visible oil leaks around the top of the engine. Check engine light (CEL) due to misfires caused by oil seeping into the spark plug wells. Engine running rough or noticeable performance issues. Causes: High engine temperatures causing gasket material to degrade. Normal wear and tear due to age and usage. Improper installation or over-tightening during previous repairs. Waiting too long between oil changes; Extended oil change intervals leading to sludge buildup, which accelerates wear. Potential Consequences : If left unchecked, a valve cover gasket leak can lead to more severe problems, such as damaged ignition coils or fouled spark plugs. This can result in misfires, reduced fuel efficiency, and costly repairs. How We Fix It : At TMJ Bimmers, we replace the valve cover gasket with a high-quality OEM or aftermarket part, ensuring proper torque specifications to prevent future leaks. We also inspect the valve cover itself for cracks, which can occur on older models. After the repair, we thoroughly clean the area to remove any residual oil. 2. Oil Filter Housing Gasket Leak What It Is : The oil filter housing gasket seals the connection between the oil filter housing and the engine block. Over time, this gasket can deteriorate, leading to leaks. This issue is particularly common in turbocharged BMW engines, such as the N54 and N55. Signs of a Problem: Oil pooling near the front of the engine. Unexplained decreased oil levels between oil changes. Visible oil stains on the engine or driveway. Unusual engine noises caused by low oil pressure. Causes : Exposure to heat and pressure, which breaks down gasket material over time. Age-related wear, especially in vehicles with over 60,000 miles. Poor-quality replacement gaskets from previous repairs. Waiting too long between oil changes; Delayed oil changes causing sludge buildup around the gasket. Potential Consequences: Ignoring an oil filter housing gasket leak can cause engine components to wear prematurely. It can also lead to low oil pressure, which in extreme cases, can result in engine failure. How We Fix It: We’ll replace the failing gasket and thoroughly clean the area to ensure no residual oil remains. During the repair, we’ll inspect nearby components like the oil cooler gasket, as it’s often affected in tandem. Additionally, we check for oil contamination in the cooling system, which can occur if the issue is left unresolved for too long. 3. Oil Pan Gasket Leak What It Is: The oil pan gasket seals the oil pan to the bottom of the engine. This gasket can fail, especially in older or high-mileage BMWs. Vehicles that experience frequent stop-and-go driving or those exposed to harsh road conditions are particularly susceptible. Signs of a Problem: Oil spots on your garage floor or driveway. Visible oil dripping from the underside of the car. Low oil level warning on the dashboard. Increased oil consumption requiring frequent top-offs. Causes: Damage from road debris or impacts causing stress on the oil pan. Long-term wear and exposure to heat, which weakens gasket material. Over-tightened bolts leading to gasket compression and failure. Improper installation during previous repairs. Potential Consequences : An untreated oil pan gasket leak can lead to low oil levels, causing inadequate lubrication of engine components. Over time, this can result in excessive wear, overheating, and potentially catastrophic engine damage. How We Fix It: Replacing an oil pan gasket involves removing the oil pan, cleaning the mating surfaces, and installing a new gasket. This process requires precision and care, as improper installation can lead to further leaks. While the oil pan is off, we inspect for sludge or debris to ensure the engine stays in optimal condition. We also replace the engine oil and filter as part of the service. Why Do BMWs Experience Oil Leaks? BMWs are known for their precision engineering and high-performance engines. However, these characteristics also make them more prone to oil leaks due to: Higher operating temperatures compared to many other vehicles. The use of synthetic oil, which can expose weaknesses in gaskets over time. Complex engine designs with multiple gaskets and seals. Regular maintenance and timely repairs are key to keeping your BMW in peak condition. Why Choose TMJ Bimmers for Your BMW Repairs? Oil leaks are more than just a nuisance—they can compromise your engine’s performance and longevity. At TMJ Bimmers, we specialize in BMW maintenance and repairs, offering: Expertise : Our team is trained to diagnose and repair common BMW issues efficiently. High-Quality Parts : We use OEM and premium aftermarket parts to ensure durability and reliability. Transparent Communication : We’ll walk you through the repair process and provide clear, upfront pricing. Comprehensive Inspections : Every repair includes a thorough inspection to identify and address potential issues before they escalate. If you suspect your BMW has an oil leak, don’t wait for the problem to worsen. Contact us today at 713.384.2273 or visit tmjbimmers.com to book your appointment at our Houston shop to have your vehicle inspected. Let’s keep your BMW running smoothly and leak-free for miles to come!

TMJ Bimmers Euro Auto Repair

Mon - Fri 8:00am - 6:00pm

Payment Options

Services

List of Services

-

Air Conditioning ServiceAir Conditioning Service

-

Alignment SpecialistAlignment Specialist

-

Battery ServicingBattery Servicing

-

Brake Inspection and ServiceBrake Inspection and Service

-

Check Engine Light ServicesCheck Engine Light Services

-

Complete Computer DiagnosticsComplete Computer Diagnostics

-

Coolant Systems RepairCoolant Systems Repair

-

Differential & Transfer Case ServicingDifferential & Transfer Case Servicing

-

Electrical System RepairElectrical System Repair

-

Engine Service and RepairEngine Service and Repair

-

Muffler & Exhaust System Repair and UpgradeMuffler & Exhaust System Repair and Upgrade

-

Fuel System ServiceFuel System Service

-

Oil ChangeOil Change

-

Performance & Transmission TuningPerformance & Transmission Tuning

-

Pre-Purchase InspectionsPre-Purchase Inspections

-

Road-Force Wheel BalancingRoad-Force Wheel Balancing

-

Steering and SuspensionsSteering and Suspensions

-

Timing Chain Issues & RepairsTiming Chain Issues & Repairs

-

Transmission Repair and ServiceTransmission Repair and Service

List of Services

-

Air Conditioning ServiceAir Conditioning Service

-

Alignment SpecialistAlignment Specialist

-

Battery ServicingBattery Servicing

-

Brake Inspection and ServiceBrake Inspection and Service

-

Check Engine Light ServicesCheck Engine Light Services

-

Complete Computer DiagnosticsComplete Computer Diagnostics

-

Coolant Systems RepairCoolant Systems Repair

-

Differential & Transfer Case ServicingDifferential & Transfer Case Servicing

-

Electrical System RepairElectrical System Repair

-

Engine Service and RepairEngine Service and Repair

-

Muffler & Exhaust System Repair and UpgradeMuffler & Exhaust System Repair and Upgrade

-

Fuel System ServiceFuel System Service

-

Oil ChangeOil Change

-

Performance & Transmission TuningPerformance & Transmission Tuning

-

Pre-Purchase InspectionsPre-Purchase Inspections

-

Road-Force Wheel BalancingRoad-Force Wheel Balancing

-

Steering and SuspensionsSteering and Suspensions

-

Timing Chain Issues & RepairsTiming Chain Issues & Repairs

-

Transmission Repair and ServiceTransmission Repair and Service

Services

List of Services

-

Air Conditioning ServiceAir Conditioning Service

-

Alignment SpecialistAlignment Specialist

-

Battery ServicingBattery Servicing

-

Brake Inspection and ServiceBrake Inspection and Service

-

Check Engine Light ServicesCheck Engine Light Services

-

Complete Computer DiagnosticsComplete Computer Diagnostics

-

Coolant Systems RepairCoolant Systems Repair

-

Differential & Transfer Case ServicingDifferential & Transfer Case Servicing

-

Electrical System RepairElectrical System Repair

-

Engine Service and RepairEngine Service and Repair

List of Services

-

Air Conditioning ServiceAir Conditioning Service

-

Alignment SpecialistAlignment Specialist

-

Battery ServicingBattery Servicing

-

Brake Inspection and ServiceBrake Inspection and Service

-

Check Engine Light ServicesCheck Engine Light Services

-

Complete Computer DiagnosticsComplete Computer Diagnostics

-

Coolant Systems RepairCoolant Systems Repair

-

Differential & Transfer Case ServicingDifferential & Transfer Case Servicing

-

Electrical System RepairElectrical System Repair

-

Engine Service and RepairEngine Service and Repair

-

Muffler & Exhaust System Repair and UpgradeMuffler & Exhaust System Repair and Upgrade

-

Fuel System ServiceFuel System Service

-

Oil ChangeOil Change

-

Performance & Transmission TuningPerformance & Transmission Tuning

-

Pre-Purchase InspectionsPre-Purchase Inspections

-

Road-Force Wheel BalancingRoad-Force Wheel Balancing

-

Steering and SuspensionsSteering and Suspensions

-

Timing Chain Issues & RepairsTiming Chain Issues & Repairs

-

Transmission Repair and ServiceTransmission Repair and Service

© 2024 TMJ Bimmers Euro Auto Repair. All Rights Reserved | Website managed by Shopgenie